High pressure testing unit

Test bench for a high pressure gas, unparalleled anywhere in the world in terms of its characteristics, is designed for full-scale testing of various oil and gas equipment at a pressure up to 120 bars with the gas mixtures of different compositions.

The stand allows simulating a wide range of parameters at the inlet and outlet of equipment with the following gas mixtures:

- Methane with a supplement of propane, butane, pentane (natural or associated gas of ordered composition is simulated);

- Air;

- Carbon dioxide;

- Nitrogen;

- Oxygen and others.

Specifications:

- Flow: 100 - 10,000 nm3/h

- Pressure: 1 atm - 120 atm

- Temperature: -80°C - +80°C

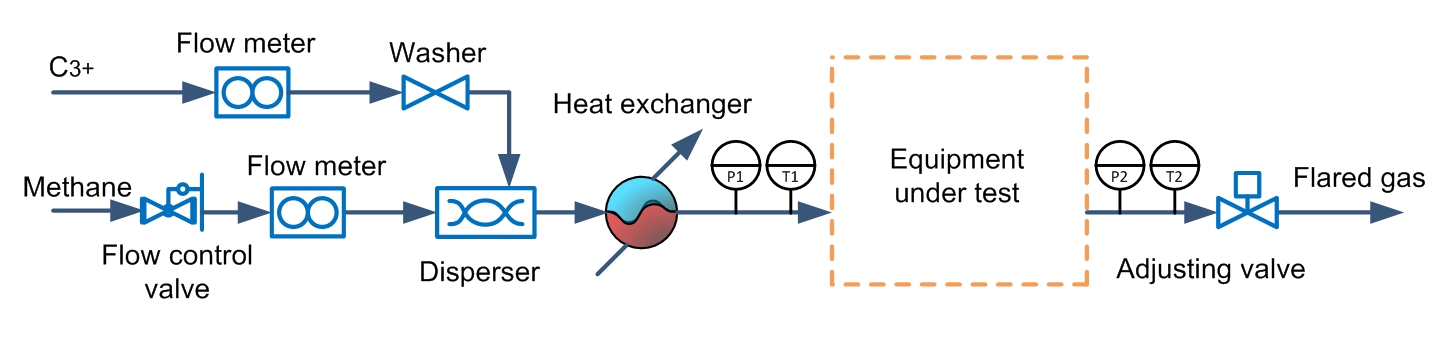

The Figure presents the test stand schematic.

The pressure of methane is raised to 120 atm or more by means of existing compressor station. Via the reducing valve and flow meter nozzle, the compressed gas is supplied to the inlet of tested equipment with the specified flow and pressure. Tests can be conducted in both static (at a constant gas pressure and flow rate at the inlet) and dynamic conditions (at a varying gas pressure and flow rate at the inlet).

There is a heat exchanger on the test stand, used to change the temperature of the gas, supplied to the inlet of equipment under test. It is possible to heat the flow by hot air or to cool it by liquid nitrogen, and this delivers performance in a wide temperature range at the inlet of equipment.

Gas composition can be simulated at the inlet of tested equipment as required, for this purpose there is a delivery line of liquid propane, pentane and other cut fractions, which are injected into the flow before the heat exchanger through a dedicated dispergator.

All parameters at the inlet and outlet of the equipment under test, as well as the operating parameters of equipment are registered in a real time. Gas after the equipment is fed to the existing flare facilities for the secondary combustion.

Utilized measuring instruments:

- Gas and liquid flow meters;

- Sensors for measuring temperature, pressure, differential pressure;

- Chromatograph;

- Dew point analyzer.

In terms of test completeness and measurement of all parameters the test stand can be equipped with the necessary equipment to meet all Customer requirements.