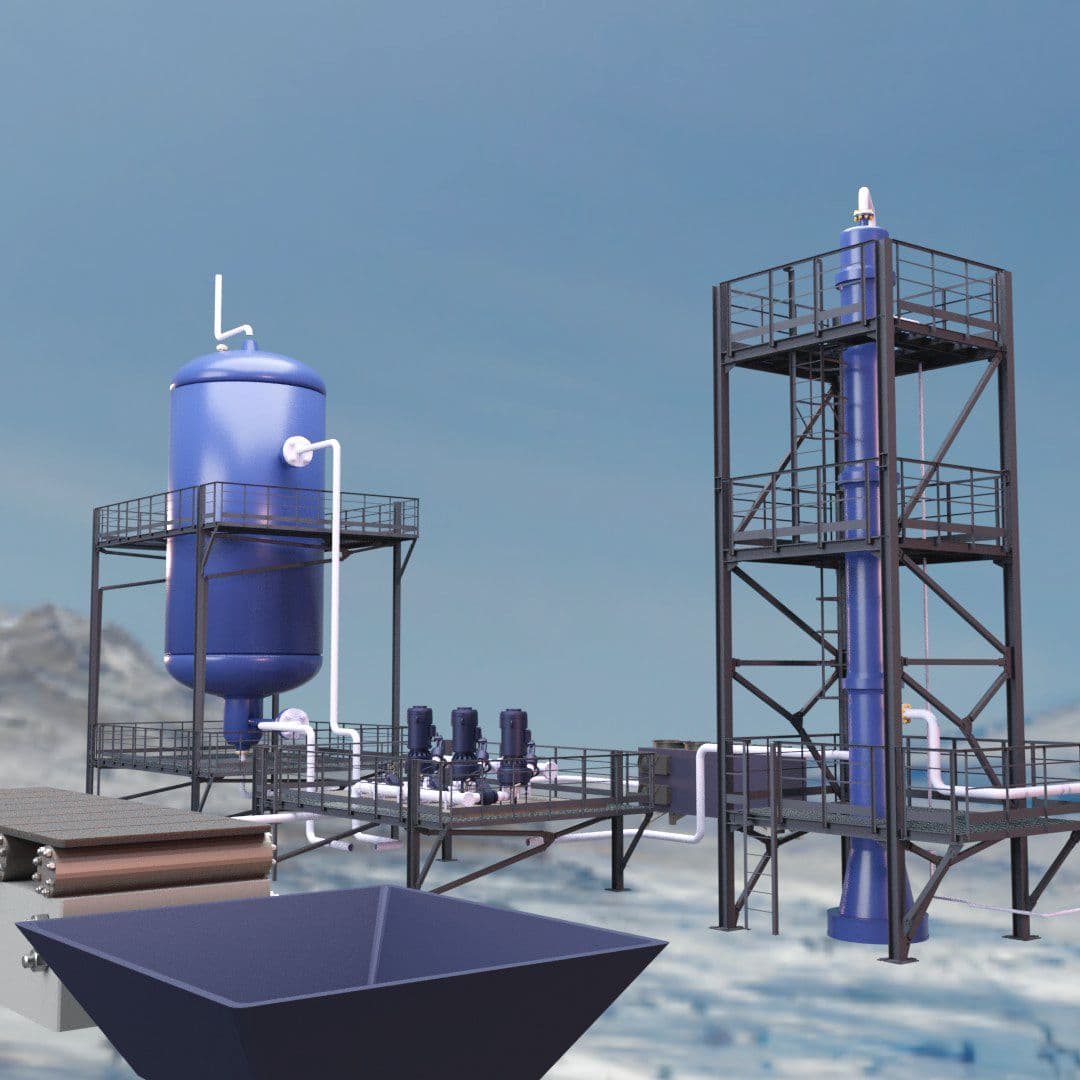

Waste-Free Desulfurization Units

Applications of SRP Technology:

▸ Desulfurization of natural gas and associated petroleum gas (including before power generation centers)

▸ Hydrogen sulfide removal from associated gas at wellheads

▸ Absorption of hydrogen sulfide from acidic amine streams

▸ Enhancing flexibility and efficiency of Claus units

▸ Purification of sour petroleum gas containing up to 500 ppm hydrogen sulfide

▸ Desulfurization of up to 200 m³/min of gas at refineries

▸ Desulfurization in lubricating oil production units

▸ Hydrogen sulfide emission control at geothermal power plants

▸ Desulfurization of natural gas and associated petroleum gas (including before power generation centers)

▸ Hydrogen sulfide removal from associated gas at wellheads

▸ Absorption of hydrogen sulfide from acidic amine streams

▸ Enhancing flexibility and efficiency of Claus units

▸ Purification of sour petroleum gas containing up to 500 ppm hydrogen sulfide

▸ Desulfurization of up to 200 m³/min of gas at refineries

▸ Desulfurization in lubricating oil production units

▸ Hydrogen sulfide emission control at geothermal power plants

Dependence on Imported Components:

Completely independent

Completely independent

Advantages:

▸ No tail gas – elemental sulfur is produced

▸ Low CAPEX and OPEX compared to amines and adsorbents

▸ Utilizes acidic absorbents

▸ Ideal for low H₂S content in feed (up to 2% by mass) and for gas purification before power generation units

▸ Low CAPEX and OPEX compared to amines and adsorbents

▸ Utilizes acidic absorbents

▸ Ideal for low H₂S content in feed (up to 2% by mass) and for gas purification before power generation units

Application Experience:

▸ Successfully operating at Dobrinskoye Gas Processing Plant (VolgaGas) at a flow rate of 40,000 Nm³/h

▸ Successfully developed a mobile pilot desulfurization unit with a flow rate of 300 Nm³/h for gas purification before AGGREKO power generation center

▸ Successfully operating at Dobrinskoye Gas Processing Plant (VolgaGas) at a flow rate of 40,000 Nm³/h

▸ Successfully developed a mobile pilot desulfurization unit with a flow rate of 300 Nm³/h for gas purification before AGGREKO power generation center