Production Asset Operation Optimization: Current Situation and Potential Solution

OBJECTIVE:

Identifying optimization solutions for equipment operation modes in the production and preparation chain:

• Production allocation across wells

• Selection of fractionation column operating mode

• Optimization of low-temperature separation processes

• Compressor equipment efficiency

• Production allocation across wells

• Selection of fractionation column operating mode

• Optimization of low-temperature separation processes

• Compressor equipment efficiency

CHALLENGES:

• Using models for decision-making in "manual mode" requires significant time to generate optimization variants for control

• Specialized personnel are needed to operate the solution and derive operational mode variants for the facility

SOLUTION:

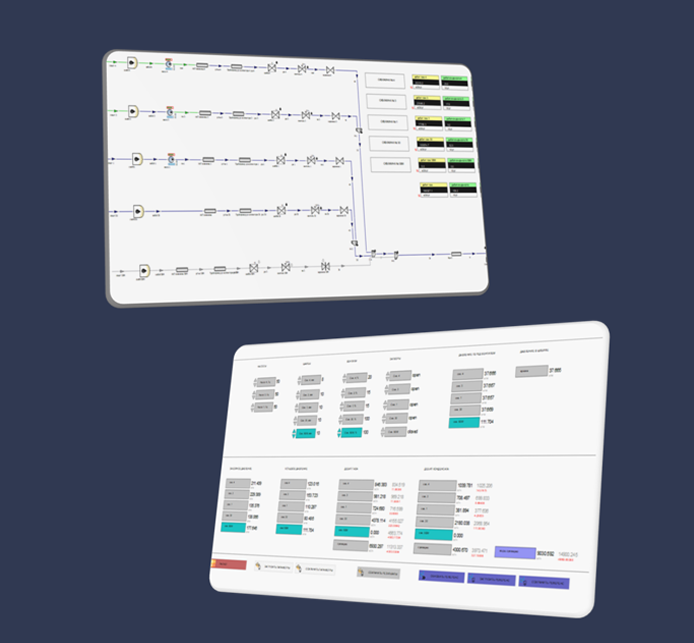

• Real-time integrated digital twin automatically calculates product flow parameters through equipment

• Virtual sensor system, based on digital twins, provides flow parameters at any asset section (temperature, pressure, component composition)

• Optimization algorithms automatically generate optimal equipment operation variants to increase target product output

• Specialized personnel are needed to operate the solution and derive operational mode variants for the facility

SOLUTION:

• Real-time integrated digital twin automatically calculates product flow parameters through equipment

• Virtual sensor system, based on digital twins, provides flow parameters at any asset section (temperature, pressure, component composition)

• Optimization algorithms automatically generate optimal equipment operation variants to increase target product output

POTENTIAL BUSINESS BENEFITS:

• Forecasting profit maximization for the asset’s target product

• Increased output of target commercial products (LPG, stable condensate)

• Energy savings

• Reduced methanol usage costs

• Improved commercial product quality (compliance with standards)

• Forecasting profit maximization for the asset’s target product

• Increased output of target commercial products (LPG, stable condensate)

• Energy savings

• Reduced methanol usage costs

• Improved commercial product quality (compliance with standards)

Implemented Business Projects: Dobrinsky GKM Example

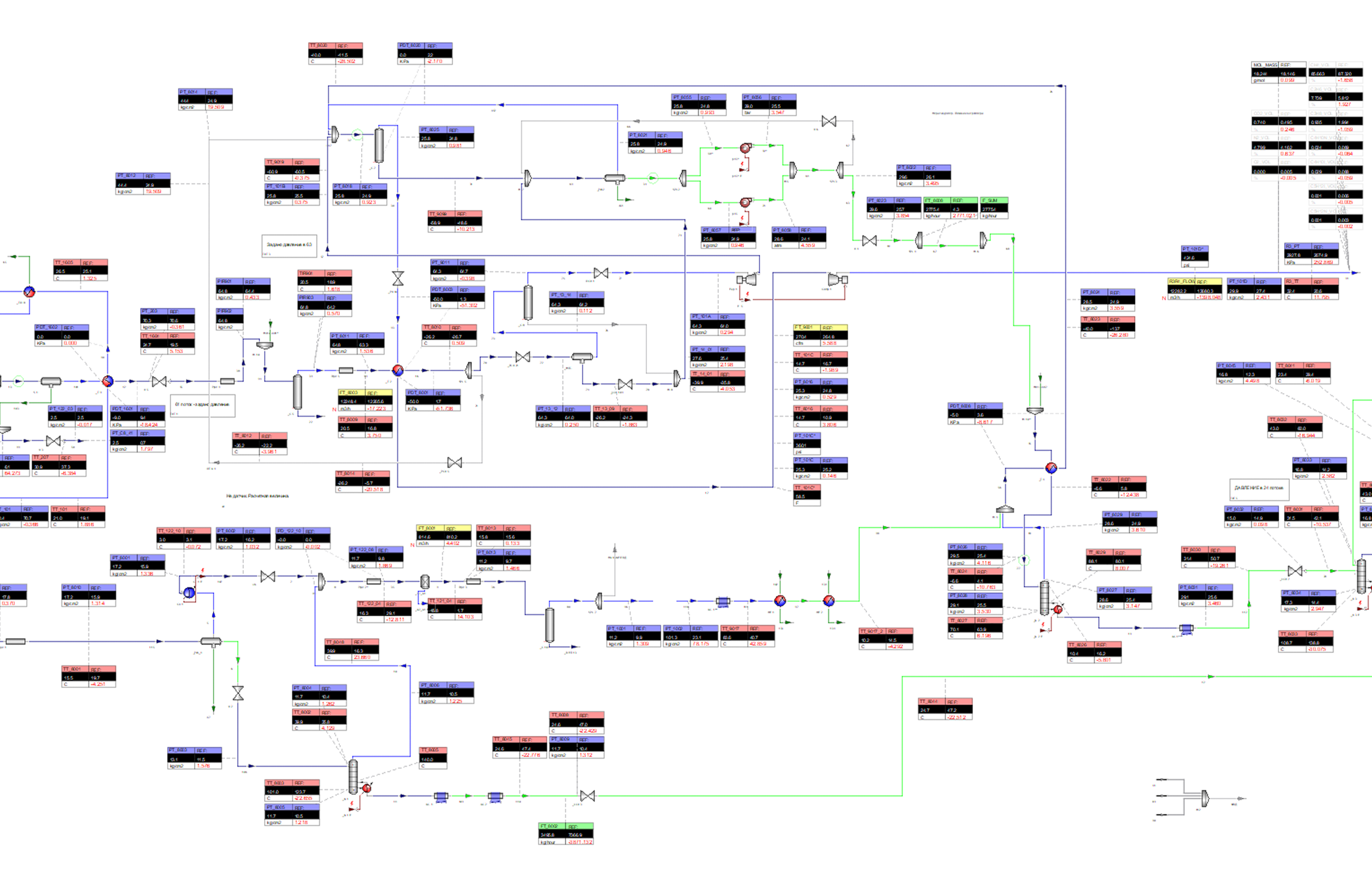

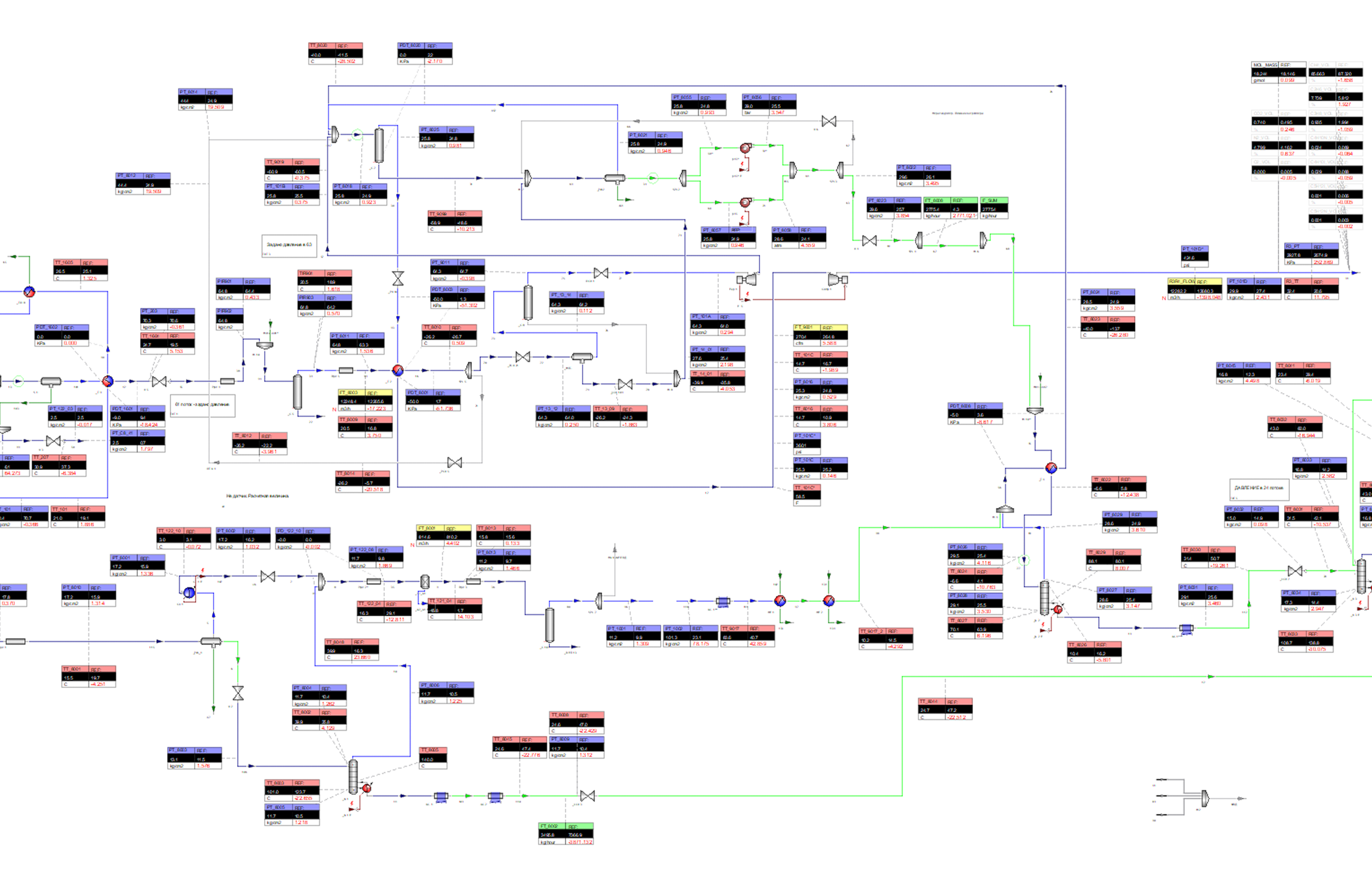

Digital Twin of GPP

Results:

• Optimized column equipment and LTS section, increasing target product yield by 4%

• Optimized propane refrigeration unit to reduce inlet temperature for low-temperature separation by 20°C

• Forecasted GPP operation mode when replacing ejector unit with turboexpander

Digital Twin of Well Stock and Gas Collection Network

Results:

• Digital twin enabled assessment of well park operation mode changes upon commissioning a new well (well was under drilling during twin creation).

• Digital twin enabled assessment of well park operation mode changes upon commissioning a new well (well was under drilling during twin creation).

• Model allowed evaluation of flow rate and component composition changes for each well and at GPP inlet

Potential Business Benefits

up to

5%

Increase in C₃+ component recovery

up to

4.2%