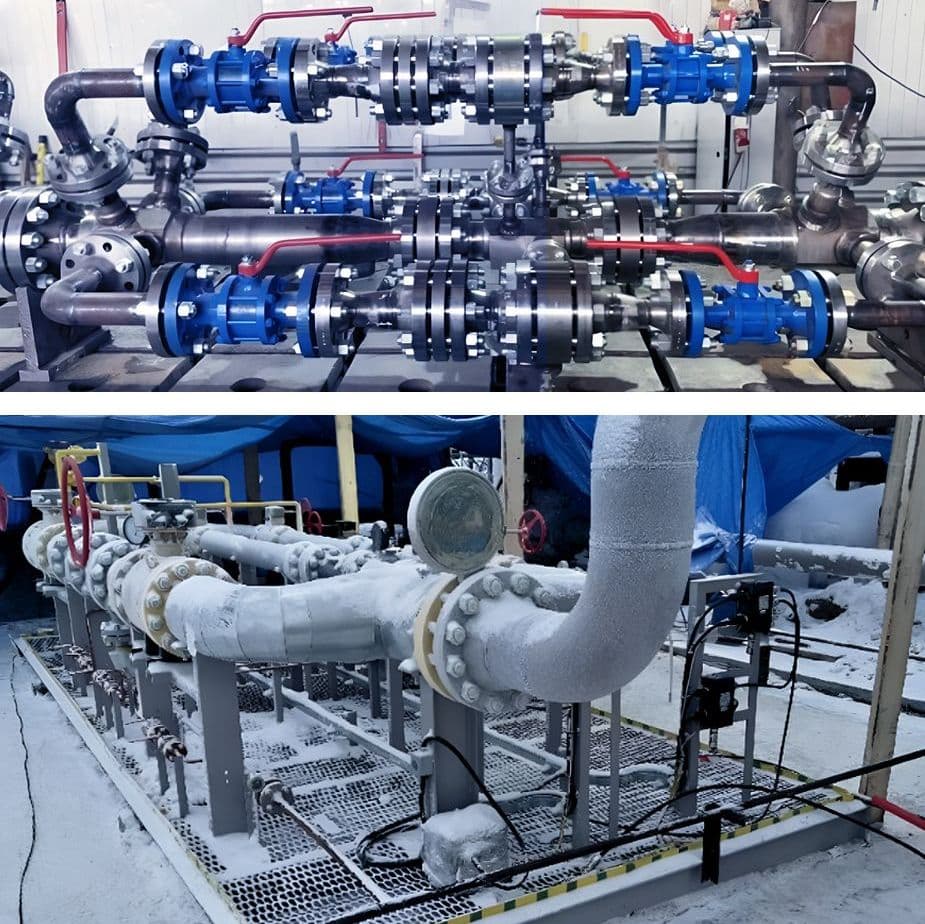

Self-Regulating Ejectors and Gas Ejection Systems

Description, Purpose, and Application:

▸ Two-stage ejector unit – Bashneft PJSC – 2016

▸ 2 units – Ejector as part of the Dobrinskoye Gas Processing Plant NTS (VolgaGas) – 2016

▸ 4 units – As part of a liquid droplet carryover prevention unit – Terneftegaz JSC (NOVATEK) – 2018, 2020, 2021

▸ Ejection unit as part of a gas preparation facility – Embamunaigas JSC – 2020

▸ Ejection unit for YATEK PJSC – 2020

Gas ejectors (jet compressors) are devices that utilize excess pressure of high-pressure gases to compress low-pressure gases and deliver them to field gas collection and processing systems.

To determine the stable operating conditions of ejector systems, computational methods for real gas flows are used, previously applied to analyze flows around aerospace vehicles.

Application Experience:

To determine the stable operating conditions of ejector systems, computational methods for real gas flows are used, previously applied to analyze flows around aerospace vehicles.

Application Experience:

▸ Two-stage ejector unit – Bashneft PJSC – 2016

▸ 2 units – Ejector as part of the Dobrinskoye Gas Processing Plant NTS (VolgaGas) – 2016

▸ 4 units – As part of a liquid droplet carryover prevention unit – Terneftegaz JSC (NOVATEK) – 2018, 2020, 2021

▸ Ejection unit as part of a gas preparation facility – Embamunaigas JSC – 2020

▸ Ejection unit for YATEK PJSC – 2020

Technical Specifications:

▸ Adjustable ejector systems adapt to changing input parameters.

▸ Maintenance-free operation

▸ Low operating costs

▸ Fast payback, cost-effective compared to mechanical pumps/compressors

▸ Resistant to solid phase presence

▸ Suitable for installation in hard-to-reach locations (offshore, subsea, floating, onshore)

▸ Environmentally friendly – zero emissions

Completely independent

▸ Adjustable ejector systems adapt to changing input parameters.

▸ Maintenance-free operation

▸ Low operating costs

▸ Fast payback, cost-effective compared to mechanical pumps/compressors

▸ Resistant to solid phase presence

▸ Suitable for installation in hard-to-reach locations (offshore, subsea, floating, onshore)

▸ Environmentally friendly – zero emissions

Advantages:

▸ Compressor-less compression of natural and associated petroleum gases;

▸ Increased flow rates from low-pressure wells in gas and gas-condensate fields;

▸ Reduced compressor power requirements;

▸ Utilization of flare and other low-pressure gases, etc.

Dependence on Imported Components:

▸ Increased flow rates from low-pressure wells in gas and gas-condensate fields;

▸ Reduced compressor power requirements;

▸ Utilization of flare and other low-pressure gases, etc.

Dependence on Imported Components:

Completely independent