Gas treatment and processing facilities

AEROGAS LLC identifies opportunities for obtaining additional profit at existing capacities of its Customers (CGTP, Oil Absorption Units, Gas Fractionation plants, Condensate Deethaniziser Plants, Gas-Gathering Systems, BPS, BCS, etc.) and proposes a turnkey solutions improving Companies efficiency in the following areas:

- Efficient utilization of low-pressure gases (flare, weathering, etc.);

- Disposal of Associated Petroleum Gas;

- Prevention of carryover of dropping liquid from top of separators and columns;

- Optimization of compressorless gas pumping in underground storage facilities;

- Compressorless enhanced gas recovery of low-pressure gas, gas-condensate and wet wells;

- Compressorless increase in capacity of existing gas gathering and transport system;

- Accurate measurement of the amount of oil produced in oil wells with a high gas factor;

- Precise quantity measurement of crude oil produced in high gas-oil ratio oil wells;

- Self-generated power supply of remote gas and gas condensate wells, etc.

AEROGAS LLC successfully handles such tasks through adoption of compact tailor-made process units and their favorable location in the existing technological scheme. It should be noted that the implementation of these measures does not require the facility renovation, its shutdown for erection, and all engineering solutions are connected to operating production at several points.

AEROGAS LLC maintains the project at all stages of its implementation, from the PFS (Project Feasibility Study) to the supervision-installation activity, start-up and commissioning works.

AEROGAS LLC implements EPC-contracts for supply of various gas processing and treatment facilities, intended for conditioning of APG, natural gas and other gases to the required levels. If necessary, the gas composition can be corrected (removal of undesirable gas components). Depending on the input data provided by the Customer, AEROGAS specialists develop the technological scheme of the unit, perform calculations of heat and material balance, in close coordination with the suppliers work out the main equipment design, its layout and packaging arrangement, conduct a technical-and-economic assessment.

Gas treatment and LPG recovery plants

AEROGAS carries out engineering of gas facilities meant for the target components extraction and dew point gas treatment.

The recovery of liquid hydrocarbons ensures:

- the sales gas compliance with specification (gross heating value) and hydrocarbons and water dew-point requirements;

- a complete liquefaction of C3+, including partial deethanization (by means of AEROGAS facilities), when the deep cut of heavy hydrocarbons is required.

Technology solutions of AEROGAS in the projects of CGTP, condensate fractionation and stabilization units are able to exclude highly expensive:

- Refregiration (propane cooling unit)

- Isentropic / isenthalpic expansion

- Dehydration

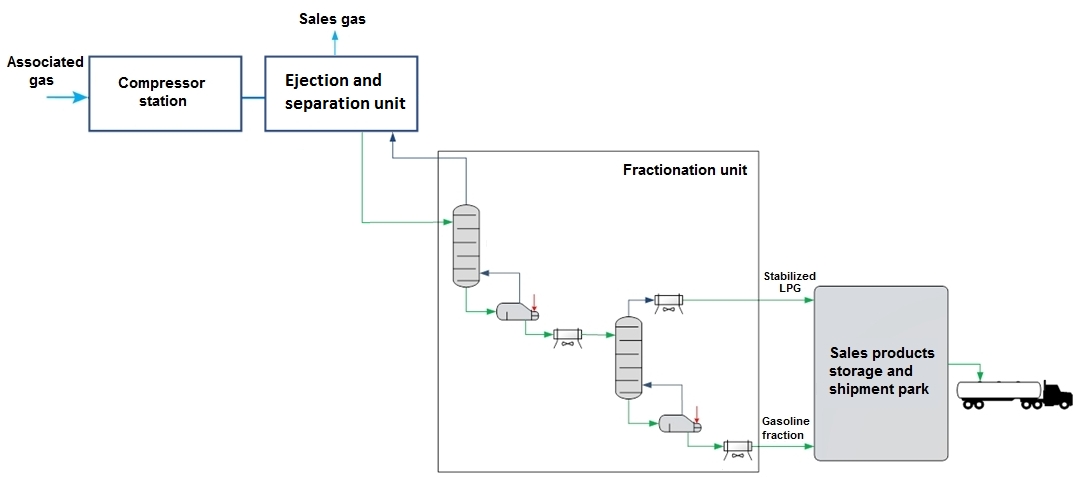

The low-temperature separation units delivered by AEROGAS LLC differ from traditional ones by the presence of special compact ejector-separation units.

The owning cost of such units is much lower compared to traditional technological solutions. Thanks to AEROGAS LLC solutions it’s possible to:

- reduce the capital costs for CGTP construction in 2-4 times due to the compressor-free gas treatment;

- boost production of existing CGTP up to 2 times of the initial consumption of the inlet feed;

- increase the extraction of desired cut (C3 +) at existing CGTP up to 90% without the use of turbines and chillers;

- at the design stage establish measures preventing the liquid carryover from the top of distillation columns;

- dispose of up to 100% flare gases and other low-pressure gases.

Joint engineering

The joint with famous Italian engineering company ISG SpA russian-italian company OOO ISG, which supplies to the Russian market adsorption, absorption, membrane and other units for covering a very wide range of issues of oil and gas and petrochemical industry

Sulfur Removal Units

AEROGAS represents sour components (H2S and CO2) removal units in Russia.

Sweetening units, depending on acidic components concentration, are based on:

- Absorption - for CO2 or CO2 and H2S removal

Amine treating is a well-known technology used for removal of H2S and CO2 through absorption and chemical reaction. The solvent selection depends on process parameters and each of the alkanolamines gives an advantage to the following treatment processes: MEA, DEA, MDEA, DGA, Special solvents.

Sour gas is fed to the absorber where it contacts lean amine solution, which further goes down the column. The acid gas components, H2S and/or CO2, are absorbed by the amine solution and the sweet gas leaves the absorber for further processing. The rich amine is sent to a regeneration system where is treated to be recycled as lean amine to the contactor.

- Membrane - for CO2 removal.

Membranes are simple and safe CO2 removal system. The number of membranes depends on the gas flow and its concentration. Membranes separate the CO2 from the gas by filtering method. The advantage of Membrane system is that is simple unit, easy to operate, without the need for complex maintenance and for remote area or space weight restriction (offshore platforms) is the best solution. - Adsorption - for the removal of sulfur compositions from low to low-low levels

To remove mercaptans, H2S, COS, CS2, complete conversion of the sulfur compounds to H2S and subsequent removal of H2S, we offer molecular sieves. Different adsorbent and catalyst are selected and loaded into the various reactors and adsorbers, where the refining process is performed. AEROGAS jointly with ISG delivers a complete system with the necessary equipment to ensure a continuous and smooth operation.

Dehydration Units

Depending on requirements the operating principle of Dehydration Units is based on the use of molecular sieves or silica gels (DEG, TEG). When molecular sieves are used, the depth of dehydration can reach -100 degrees Celsius.

Helium Recovery Units

Small and Medium PSA Units